Silver Ag based solder is usually an alloy dominated by silver or silver based solid solution. This kind of solder has excellent process performance, low melting point, good wettability and caulking performance, excellent strength, plasticity, conductivity and corrosion resistance. It can be used to braze almost all ferrous and non-ferrous metals except aluminum, magnesium and other low melting point metals, so it has been widely used.

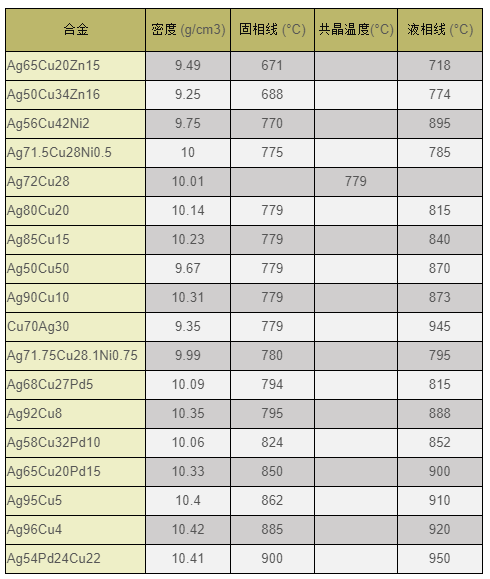

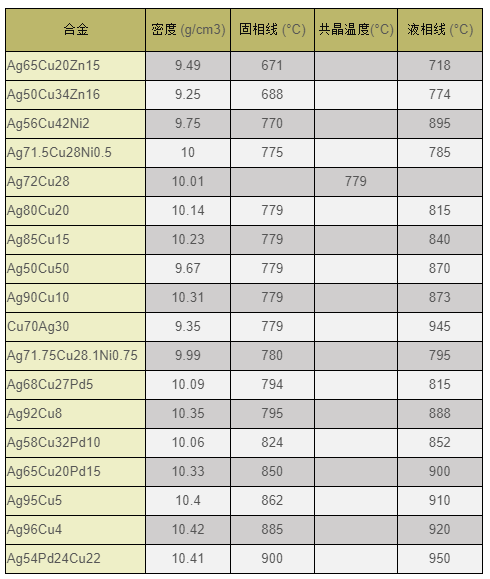

There are many kinds of silver based solders, but almost all the commonly used silver based solders contain copper. In order to reduce the melting point and silver content, alloying elements such as zinc, nickel and cadmium are usually added to form ternary or multicomponent alloys.

Ag72cu28 is the most widely used eutectic solder in electric vacuum devices. It has low melting point, no temperature interval during crystallization, good brazing process performance, good wettability and fluidity on copper and nickel, and good conductivity. However, this solder has high brittleness, low strength and poor wettability to stainless steel, alloy steel and superalloy. Therefore, when brazing this kind of workpiece, copper or nickel should be plated on the brazed surface in advance to improve the wetting and spreading performance of solder. The filler metal can also be used for the front stage brazing of titanium and titanium alloys.

The properties of ag50cu50 are close to those of ag72cu28, but the silver content is low, which improves the plasticity. However, the melting temperature range increases, which is suitable for brazing wide gap joints, and can be used for pre stage brazing in multi-stage brazing.

Ag92cu8 has good fluidity, and its strength and corrosion resistance are improved compared with the first two. It is mainly used for brazing titanium and titanium alloy, titanium and stainless steel. Due to the high melting point, it can be used for the first stage brazing of graded brazing.

Agmn has high melting point and good high temperature strength. It can be used for brazing stainless steel and titanium alloy working below 400 ℃. Ag80au20 is a heat-resistant solder with excellent performance, but it is rarely used because of its high cost. Ag90pd10 has high medium temperature strength, excellent corrosion resistance, oxidation resistance and wettability, and good joint plasticity. Ag80pd20 has been further improved in strength and wettability to low alloy steel, stainless steel and superalloy. However, because the price of PD is more expensive than AG, the content of PD should be reduced as much as possible on the premise of meeting the use requirements. Ag95pd5 is developed for this purpose. Due to the extremely low vapor pressure of PD, silver palladium solder is particularly suitable for the brazing of important parts of electro vacuum or non-metal.